Air Stamping, Inc. manufactures and inventories over 2 million dollars of quality replacement parts for the Harris M1000, M1000A, M1000AI, M1000AII, M1000B, M110 folder and many others. Our segmented fountain blade and ink levelers adapt to any press. All press product lines feature quality parts and press enhancements offered as a cost effective alternative to the original manufacture.

Inside Sales:

Air Stamping has an inside sales force to field your incoming calls. Our customers speak directly to our staffed phone personnel to receive information on pricing, inventory, status and have the ability to place orders immediately.

OFFICE

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.This email address is being protected from spambots. You need JavaScript enabled to view it.This email address is being protected from spambots. You need JavaScript enabled to view it.">

Maggie Baker

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Jeff Doxsie

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Sean Roberts

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Troy Ramey

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mike Cox

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Manufacturing:

|

|

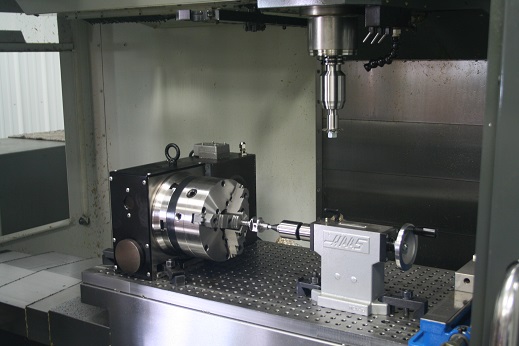

| Air Stamping has been manufacturing press parts for over 40 years. Our on-site machine shop is state of the art and equipped with CNC machining centers. Whether the process requires turning, milling or fabricating, we can control the quality in house. | |

|

|

|

|

|

|

Engineer:

Air Stamping's.skilled and knowledgeable Engineering Team has the experience and capability to design and or reverse engineer parts for your next project based on samples, prints or drawings. We have integrated an engineering system utilizing the latest technology for identifying materials, rockwell hardness, surface finishes and precise/accurate measurements. Information concerning the design of your part is collected through a Coordinate Measuring Machine and other precision instruments. This data is transformed into a three dimensional drawing or solid model. Once a model is complete we network the information to our CNC machining centers to produce a part.

Quality Control:

Without quality control we have no future. We inspect our parts to insure they meet industry specifications The printing industry requires very tight tolerances on parts and we hold our machine shop accountable to meet or exceed these tolerances. This is what has kept us a preferred supplier for all these years.

Warehouse:

Our combined office and warehousing totaling close to 15,000 square feet houses over 3,000 different part numbers. We strive to house the parts that customers need to help with breakdowns and also general maintenance. Cylinders, bearings, bushings, gears, and more are just a sampling of what we have.

|

|

Shipping & Receiving:

Our parts are shipped from our warehouse direct to you. We can ship using any carrier, by air, or ground, domestic or internationally. Extreme care is taken in packaging to protect the parts from damage during shipping.

Technology Integrators and Air Stamping understands the printing industry and the requirements that the printers expect. Our dedication to parts, enhancements and special engineering has kept us a leader in the industry for 40 years.

Our Address

Three Legend Park

P.O. Box 568

Effingham, IL 62401

T: (217) 342 - 1283

F: (217) 342 - 1286